I arrived in Steamboat Springs, Colorado gasping for air. The elevation is the first indication that if you’re from here, you’re made of sterner stuff. It only makes sense that Steamboat Springs is the birthplace of Moots Cycles, a company known for its titanium gravel bikes. The folks at Moots have been building gravel-focused bikes since 1981. In 1991, Moots went all-in on titanium frames and never looked back. Since then the methods for building have evolved. They now include 3D-printed titanium parts, which Moots uses to push its frame design to new limits.

What’s a Gravel Bike?

Gravel riding remains a top trend in the cycling world. A gravel bike is essentially a road bike with drop handlebars and no suspension that can accommodate a wider, deeper-treaded tire. Gravel and dirt roads are no longer off-limits, expanding the terrain you can explore. Yet gravel bikes remain fast and agile on the road.

While the rest of the world’s major bike manufacturers have just recently caught up to this trend, Moots has developed gravel-specific bikes for nearly four decades. Its long list of gravel-ready models are proof they’ve had time to think about how best to tackle varying conditions, but it’s their work with titanium that separates them from everyone else.

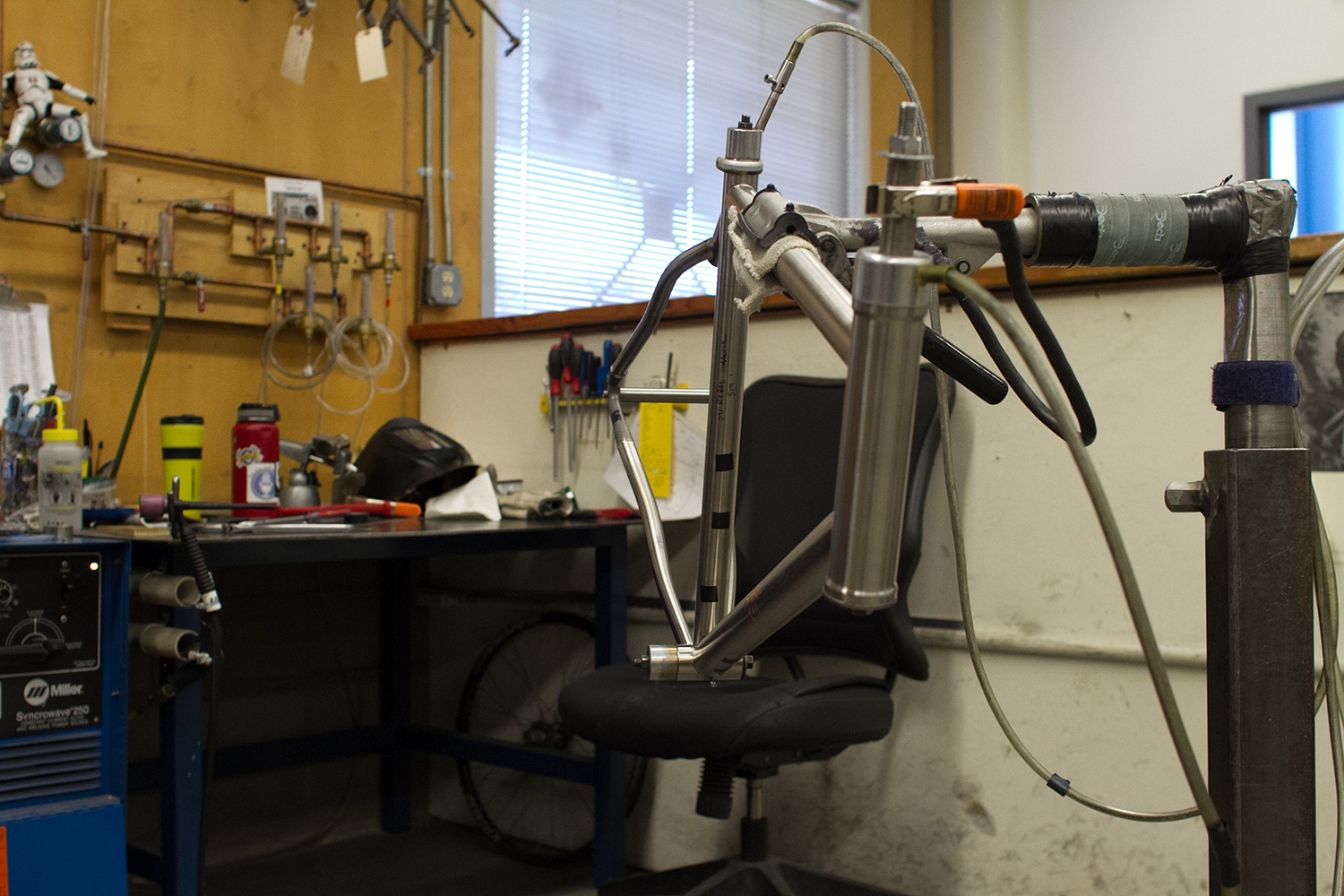

Titanium is a wonderful material for bikes. It’s light, durable, and strong. The downside? It’s very expensive to work with. The Moots factory serves testament of titanium’s challenge. From literal white glove treatment to prevent contamination, to a welding process that requires filling a frame with argon to avoid impurities, titanium is finicky to say the least.

3D printing comes to Titanium

Moots takes its exhaustive fabrication a step further with 3D printing. From unbreakable guitars to snacks , 3D printers have changed how companies prototype products. Moots, however, needs to build over 1,000 bikes a year.

For now, Moots uses 3D printing for its dropouts, which are the furthest rear points on a bike frame. Dropouts hold the rear brake caliper as well as the hub for the rear axle. It’s a focal point for abuse.

Nate Bradley, Moots’ Production Supervisor, says the titanium tubing used to build frames can’t be wrapped and formed into organic shapes like carbon fiber. Carbon fits into molds, and those molds can be designed to accommodate things like motors for e-bikes.

Titanium is a wonderful material for bikes. It’s also finicky, to say the least.

The advent of 3D printing opens similar opportunities for carbon. While Nate explained it’s unlikely Moots will ever completely 3D print a bike frame, the technology does make fabrication of detailed, complex components easier across hundreds of frames.

Building a bike for ‘shareable vision’

Many Moots bikes, like its Routt gravel bike, have evolved four or five times throughout the model’s life. While model refreshes are common in the bike industry, Moots doesn’t push out yearly updates for the sake of it. Instead, it focuses on thoughtful improvements that come about through owner and employee feedback.

These improvements are sometimes simple, like the hidden routing of cables to provide a cleaner look but can also impact the performance of a model and the “shareable vision” it must have. Nate explained this concept of shareable vision as Moots’ drive to build bikes that provide any rider, regardless of size or strength, the best experience on their bikes.

Moots doesn’t chase spec sheet supremacy. Innovation is only pursued when it makes the bike better. “Better” is subjective, and we guarantee you won’t find a manufacturer that doesn’t say their bike is the best. Still, Moots is adamant they’re designing bikes that are better for everybody, not just elite athletes looking to shave tenths of a second in a race.

Taking the Moots home

While the ride in Colorado was stunning and showcased the army of Moots advocates that showed up for the brand’s annual “Ranch Rally,” it wasn’t until I had a Routt RSL bumping along my own Oregon backroads that I realized why a titanium bike feels special.

Obviously, the components were top notch, with Shimano’s Di2 electronic shifters, Ultegra groupset, and Mavic wheels. What impressed me most, though, was how well the bike responded across both pavement and gravel. Most do-it-all bikes end up sacrificing somewhere. The result is a bike that’s good at everything, but never feels outstanding.

Most do-it-all bikes make sacrifices, but Moot’s Routt RSL is fantastic everywhere.

The Routt RSL does not succumb to this. I used it to explore miles of uncharted territory with the endurance of a road bike, but it also displayed the surefootedness of a trail bike. I felt confident everywhere I rode, from soft gravel shoulders, to single track, and all the pavement in between. This newfound freedom was exhilarating, but also made me grateful for tech in all its forms, as my Garmin Forerunner 945 never let me get too far off track.

When it came time to return our two-wheeled titanium adventure machine, it was a bittersweet moment. I was thrilled to have the chance to ride a Moots, but the Routt RSL I rode comes in at a hefty $9,740, which puts it out of our reach for most riders.

That hasn’t stopped me from trying to justify a Moots bike as an investment. The durability of titanium makes it a “buy for life” proposition, and I like that. In a day and age when far too many products are built as semi-disposable, I appreciate a company that builds its bikes to last.